Electrostatic discharge (ESD) can endanger the quality and functionality of your important electronics. When electronic components are produced or installed they need to be effectively protected by electrostatic dissipative floorings. Even discharges of as little as 100 V, which are not noticeable to a human being, can damage sensitive components.

Often, these damages are only first noticed by the customer when their units aren’t working properly. This quickly leads to high consequential costs for you because ESD protection has failed during the production process. This can result in expensive returns procedures and in customers who have lost their confidence in you.

Lower your risk with ESD flooring

From when the first semiconductors came onto the market in the 1960s, electrostatic discharges have been more than just an annoyance. Even with low potential, they endanger components in the fields of electro technology, IT, and automation.

With the right industrial flooring you can avoid the risk of ESD in data centers, production halls, laboratories and other working environments. nora has developed electrostatic dissipative flooring systems especially for electrostatic protected areas (“EPA”), which dissipate and ground the discharges in a safe and controlled manner.

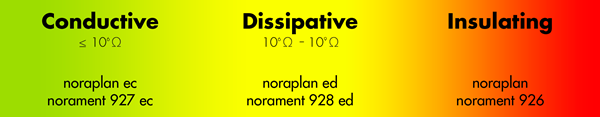

Conductive nora flooring systems (“ec”)

“ec” stands for “electrostatic conductive” and is the code used to designate our conductive flooring. Use these nora floorings if, for example, you need to protect electronic components or equip areas at risk of explosions (“ex-zones”). Conductive “ec” nora floorings have resistance to the ground up to 10⁶ Ohm. This way you can ensure quick and safe removal of any disruptive discharges.

Dissipative nora flooring systems (“ed”)

The “electrostatic dissipative” floorings from nora have a resistance to the ground of between 10⁶ and 9 x 10⁷ Ohm. This means that the flooring dissipates charges more slowly than the “ec” conductive floorings. You can use nora “ed” flooring systems in areas where components and units need to be effectively protected from ESD. Thanks to the minimum isolation they also protect people from extreme voltages.

Insulating nora flooring systems

All nora floors that are not identified with an “ec” or “ed” offer a high level of resistance to the ground and have an insulating effect. This means that you can rely on a dielective strength of up to 40 kV, which protects from high voltages (e.g. control cabinets).

No coatings, no downtime

In order to enable conductivity across the whole surface of some floorings, special coatings or waxes are needed. This layer is usually only a few micrometers thick and can therefore wear out during normal use. This means that full conductivity across the whole surface is no longer guaranteed and the surface needs to be recoated. The removal of the old coating and application of a new one more often than not entails high costs, and downtimes.

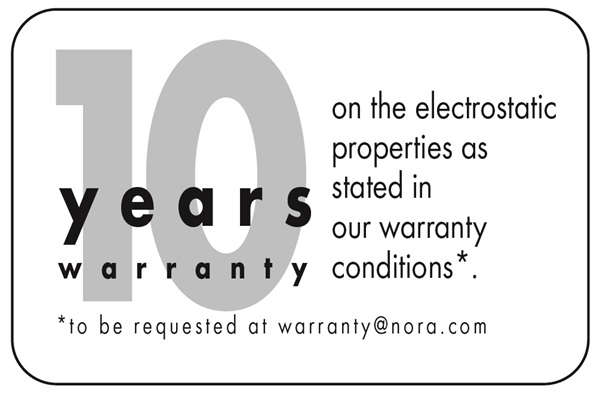

With nora floorings you can stay on the safe side, because our flooring systems are volume conductive and therefore do not require any coatings. The long downtimes required for renovation and recoating are entirely eliminated, along with any potential failure in the ESD protection. You have the long-term security of knowing the conductivity of your floor will remain unchanged. In addition, with nora industrial flooring you receive a ten-year guarantee of the electrostatic properties.

Also suitable for heavy loads

In industry, loads are usually moved with fork lifts, lift trucks or goods transportation systems. nora flooring systems can easily withstand dynamic loads of up to 6 N/mm². The electrostatic properties of the nora products remain unaffected.

Long-term effective – long-term guarantee

You get a 10-year guarantee for the electrostatic properties of our ESD industrial floors. This is dependent on the proper installation and cleaning of the material. We will be happy to send you the exact terms of the guarantee on request.

Norway | English

Norway | English